Heavy-Duty Truck Idle Reduction Technologies

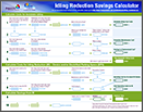

How Much Can I Save?

Use the Idle Reduction Savings Worksheet to calculate your potential savings.

Argonne National Laboratory estimates that more than one million long-haul heavy-duty trucks idle during federally required rest periods every day. Truck owners seeking to conserve fuel have a variety of choices. Many options not only save fuel, but also offer improved climate control, power for lighting and electronics, better air quality, and reduced noise. The cost-effectiveness of any approach or technology depends on the amount of idling to be offset, which depends in part on the climate where it is used. See the fact sheets Long-Haul Idling Burns Up Profits and Economics of Idling Reduction Options for Long-Haul Trucks for more information.

Idle Reduction Equipment

Technologies to reduce idling range from equipment that can be installed on trucks to provide one service or multiple services to equipment at truck stops that enables truck drivers to have climate control and power for accessories during their rest periods. These technologies include:

- Auxiliary power units

- Cab or bunk heaters

- Coolant heaters

- Energy recovery systems

- Storage air conditioners

- Automatic engine stop-start controls

- Truck stop electrification.

IdleBox contains the Idling Reduction Technology Solutions for Class 1–8 Vehicles, a database of known, currently available idling reduction equipment, the services provided (e.g., engine shut-off, heating, cooling, electric power, and cargo refrigeration), and more. The U.S. Environmental Protection Agency’s (EPA) Diesel Emissions Reduction Act (DERA) Program provides financial support for some idle reduction projects. The program includes grants and rebates for verified idle reduction technologies, among other eligible technologies. The EPA SmartWay program also offers a list of Verified Idle Reduction Technologies.