Sustainable Aviation Fuel

Sustainable aviation fuel (SAF) is an alternative fuel made from non-petroleum feedstocks that reduces emissions from air transportation. SAF can be blended at different levels with limits between 10% and 50%, depending on the feedstock and how the fuel is produced. According to the International Civil Aviation Organization (ICAO), over 360,000 commercial flights have used SAF at 46 different airports largely concentrated in the United States and Europe.

Worldwide, aviation accounts for 2% of all carbon dioxide (CO2) emissions and 12% of all CO2 emissions from transportation. ICAO's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) caps net CO2 aviation emissions at 2020 levels through 2035. The international aviation industry has set an aspirational goal to reach net zero carbon by 2050. SAF presents the best near-term opportunity to meet these goals. The Sustainable Aviation Fuel Grand Challenge, announced in 2021, brings together multiple federal agencies for the purpose of expanding domestic consumption to 3 billion gallons in 2030 and 35 billion gallons in 2050 while achieving at least a 50% reduction in lifecycle greenhouse gas emissions.

Benefits

Renewable hydrocarbon biofuels offer many benefits, including:

-

Engine and infrastructure compatibility—SAF blended with conventional Jet A can be used in existing aircraft and infrastructure.

-

Fewer emissions—Compared with conventional jet fuel, 100% SAF has the potential to reduce greenhouse gas emissions by up to 94% depending on feedstock and technology pathway.

-

More flexibility—SAF is a replacement for conventional jet fuel, allowing for multiple products from various feedstocks and production technologies.

Production

SAF can be produced from non-petroleum-based renewable feedstocks including, but not limited to, the food and yard waste portion of municipal solid waste, woody biomass, fats/greases/oils, and other feedstocks. SAF production is in its early stages, with three known commercial producers:

- World Energy began SAF production in 2016 at its Paramount, California, facility and initially supplied fuel to Los Angeles International Airport prior to supplying additional California airports.

- International producer Neste began supplying SAF to San Francisco International Airport in 2020 before expanding to other California airports in 2021 and 2022, as well as Aspen/Pitkin County Airport and Telluride Regional Airport, both in Colorado.

- Montana Renewables LLC began production in partnership with Shell at an existing petroleum production plant in 2023, supplying fuel to several partner airlines.

Additional new domestic plants are expected. Many airlines have signed agreements with existing and future SAF producers to use all their expected output. The U.S. Environmental Protection Agency (EPA) collects renewable fuel data as part of the Renewable Fuel Standard, which provides an approximate consumption for novel biofuels such as SAF. EPA's data show that approximately 5 million gallons of SAF were consumed in 2021, 15.84 million gallons in 2022, and 24.5 million gallons in 2023.

There are multiple technology pathways to produce fuels approved by ASTM and blending limitations based on these pathways. ASTM D7566 Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons dictates fuel quality standards for non-petroleum-based jet fuel and outlines approved SAF-based fuels and the percent allowable in a blend with Jet A. All three existing plants use the hydroprocessed esters and fatty acids pathway shown in the table on this page. New domestic plants using the alcohol-to-jet pathway with ethanol as a feedstock are expected. ASTM D1655 Standard Specification for Aviation Turbine Fuels allows co-processing of biomass feedstocks at a petroleum refinery in blends up to 5%.

Both ASTM standards are continuously updated to allow for advancements in technology to produce SAF. DOE's Sustainable Aviation Fuel Review of Technical Pathways provides details on various SAF production pathways. The pathways below represent only those currently approved by ASTM. Processes and tests exist for the approval of other feedstocks, fuel molecules, and blending limits, and the types of approved fuels will increase as these are evaluated through this process.

| Pathway | Approved Name | Blending Limitation | Feedstocks | Chemical Process |

|---|---|---|---|---|

| Fischer-Tropsch (FT) Synthetic Paraffinic Kerosene (SPK) | FT-SPK, ASTM D7566 Annex A1, 2009 | 50% | Municipal solid waste, agricultural and forest wastes, energy crops | Woody biomass is converted to syngas using gasification, then a Fischer-Tropsch synthesis reaction converts the syngas to jet fuel. Feedstocks include various sources of renewable biomass, primarily woody biomass such as municipal solid waste, agricultural wastes, forest wastes, wood, and energy crops. ASTM approved in June 2009 with a 50% blend limit. |

| Hydroprocessed Esters and Fatty Acids | HEFA-SPK, ASTM D7566 Annex A2, 2011 | 50% | Oil-based feedstocks (e.g., jatropha, algae, camelina, and yellow grease) | Triglyceride feedstocks such as plant oil; animal oil; yellow or brown greases; or waste fat, oil, and greases are hydroprocessed to break apart the long chain of fatty acids, followed by hydroisomerization and hydrocracking. This pathway produces a drop-in fuel and was ASTM approved in July 2011 with a 50% blend limit. |

| Hydroprocessed Fermented Sugars to Synthetic Isoparaffins | HFS-SIP, ASTM D7566 Annex A3, 2014 | 10% | Sugars | Microbial conversion of sugars to hydrocarbons. Feedstocks include cellulosic biomass feedstocks (e.g., herbaceous biomass and corn stover). Pretreated waste fat, oil, and greases also can be eligible feedstocks. ASTM approved by ASTM in June 2014 with a 10% blend limit. |

| FT-SPK with Aromatics | FT-SPK/A, ASTM D7566 Annex A4, 2015 | 50% | Same as A1 | Biomass is converted to syngas, which is then converted to synthetic paraffinic kerosene and aromatics by FT synthesis. This process is similar to FT-SPK ASTM D7566 Annex A1, but with the addition of aromatic components. ASTM approved in November 2015 with a 50% blend limit. |

| Alcohol-to-Jet Synthetic Paraffinic Kerosene | ATJ-SPK, ASTM D7566 Annex A5, 2016 | 50% | Cellulosic biomass | Conversion of cellulosic or starchy alcohol (isobutanol and ethanol) into a drop-in fuel through a series of chemical reactions—dehydration, hydrogenation, oligomerization, and hydrotreatment. The alcohols are derived from cellulosic feedstock or starchy feedstock via fermentation or gasification reactions. Ethanol and isobutanol produced from lignocellulosic biomass (e.g., corn stover) are considered favorable feedstocks, but other potential feedstocks (not yet ASTM approved) include methanol, iso-propanol, and long-chain fatty alcohols. ASTM approved in April 2016 for isobutanol and in June 2018 for ethanol with a 30% blend limit. |

| Catalytic Hydrothermolysis Synthesized Kerosene | CH-SK or CHJ, ASTM D7566 Annex A6, 2020 | 50% | Fatty acids or fatty acid esters or lipids from fat oil greases | (Also called hydrothermal liquefaction), clean free fatty acid oil from processing waste oils or energy oils is combined with preheated feed water and then passed to a catalytic hydrothermolysis reactor. Feedstocks for the CH-SPK process can be a variety of triglyceride-based feedstocks such as soybean oil, jatropha oil, camelina oil, carinata oil, and tung oil. ASTM approved in February 2020 with a 50% blend limit. |

| Hydrocarbon-Hydroprocessed Esters and Fatty Acids | HC-HEFA-SPK, ASTM D7566 Annex A7, 2020 | 10% | Algal oil | Conversion of the triglyceride oil, derived from Botryococcus braunii, into jet fuel and other fractionations. Botryococcus braunii is a high-growth alga that produces triglyceride oil. ASTM approved in May 2020 with a 10% blend limit. |

| Fats, Oils, and Greases (FOG) Co-Processing | FOG Co-Processing ASTM D1655 Annex A1 | 5% | Fats, oils, and greases | ASTM approved 5% fats, oils, and greases coprocessing with petroleum intermediates as a potential SAF pathway. Used cooking oil and waste animal fats are two other popular sources for coprocessing. |

| FT Co-Processing | FT Co-Processing ASTM D1655 Annex A1 | 5% | FT biocrude | In association with the University of Dayton Research Institute, ASTM approved 5% Fischer-Tropsch syncrude coprocessing with petroleum crude oil to produce SAF. |

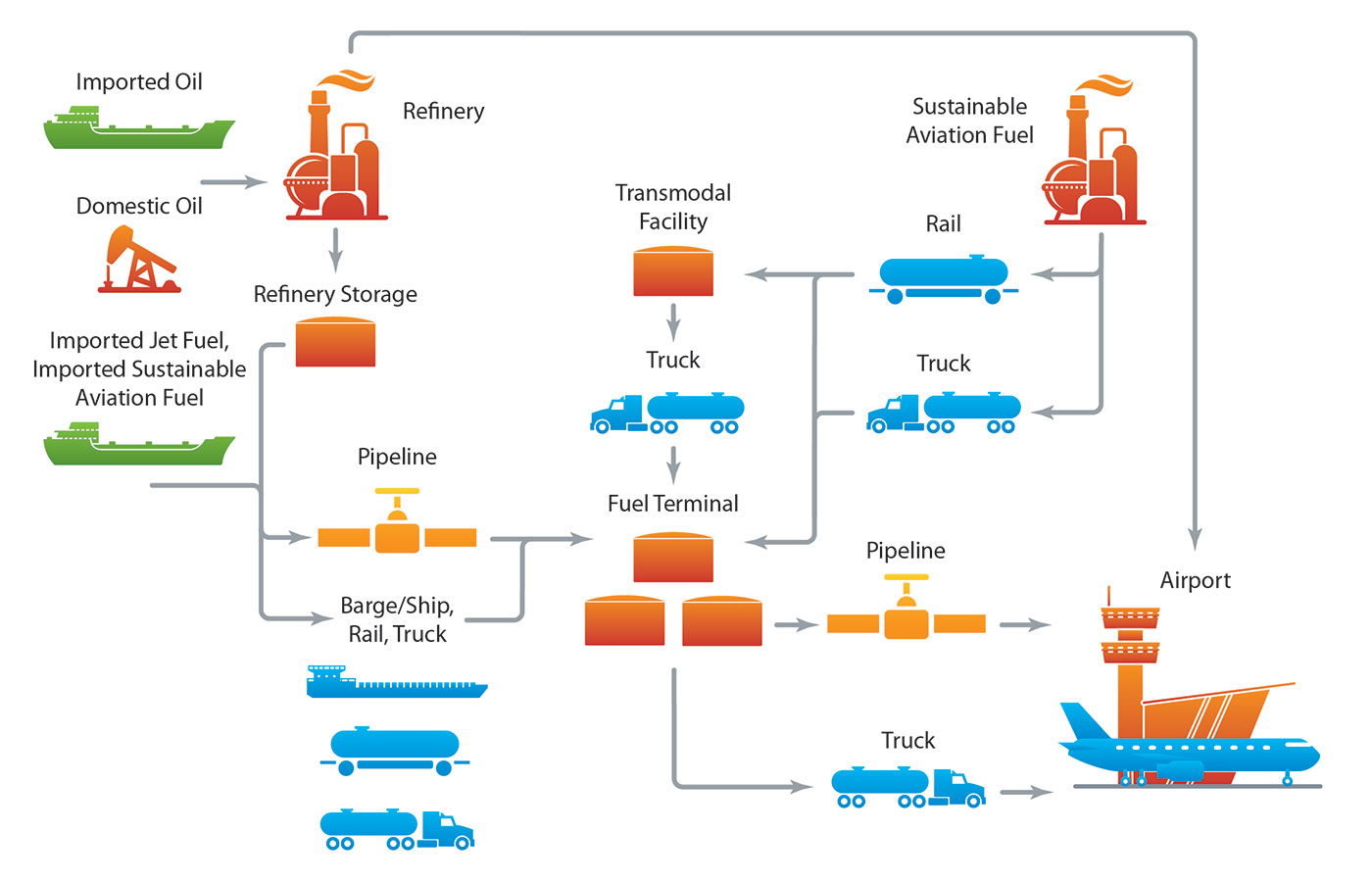

Distribution

SAF must be blended with Jet A prior to use in an aircraft. If SAF is co-processed with conventional Jet A at an existing petroleum refinery, the fuel would flow through the supply chain in a business-as-usual model via pipeline to terminals and onwards by pipeline or truck to airports. It is expected that SAF produced at biofuels facilities would be blended with Jet A at existing fuel terminals and then delivered to airports by pipeline or truck. The fuels could also be blended at the terminal directly upstream of an airport or thousands of miles away and transported by pipeline or barge to a terminal near the airport. There would be no change to fuel operations at the airport, as airports are expected to continue to receive blended fuel in the same pipelines and trucks as they do today. While it is technically possible to blend fuels at an airport, it is not the most practical or cost-effective method due to the need for additional equipment, staff, and insurance. Due to strict fuel quality standards, it is preferable to certify SAF as ASTM D1655 upstream of an airport.

Research and Development

The U.S. Department of Energy, the U.S. Department of Transportation, and the U.S. Department of Agriculture support research, development, and analysis for SAF.

More Information

Learn more about SAF at the links below. The Alternative Fuels Data Center (AFDC) and DOE do not endorse any companies or services described on this site (see disclaimer).