Electric Vehicles for Fleets

For a summary handout, download the Electric Vehicles for Fleets fact sheet.

On This Page

Electric vehicles (EVs) can fulfill many daily driving needs, making them a great solution for fleets. They offer many benefits and can fill roles in light-duty (LD), medium/heavy-duty (MD/HD), and even off-road applications.

The unique fleet environment presents considerations beyond those that consumers must address before "going electric." For example, fleet managers must understand the impacts of charging multiple vehicles while maintaining fleet operations and that larger MD/HD vehicles bring with them additional factors to consider. See EVs in Fleet Applications for more information on these considerations.

Technical assistance is also available through the Joint Office of Energy and Transportation for EV fleet implementation. Tiger Teams assistance is available for more complex, complicated challenges. Find out how to request Tiger Teams assistance.

Fleet Benefits

Lower Costs

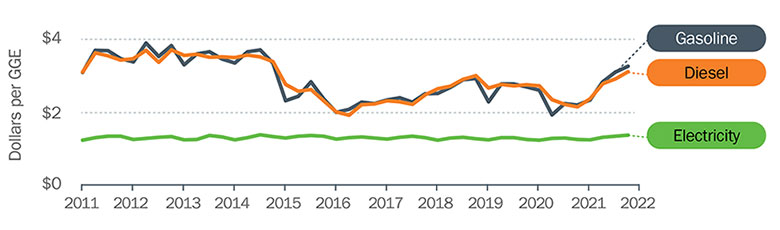

In addition to federal, state, or local incentives that can lower their purchase price, EVs offer high fuel economy, which translates to lower operating costs. Light-duty all-electric vehicle operation and maintenance (O&M) cost averages 6.1 cents per mile. EVs achieve their best fuel economy during stop-and-go driving conditions typical of many fleet applications. Electricity prices are also less volatile than those of gasoline/diesel, making it easier to predict fuel costs over time. Finally, lower off-peak electric rates may be available for charging, which further reduces EV fuel costs.

Performance Features

EVs can match or surpass the performance of their conventional counterparts, and they're much quieter. They produce maximum torque and smooth acceleration from a full stop, which can be especially useful when hauling heavy loads. Additionally, some can even serve as an energy source for off-board equipment such as power tools or lights, providing several kilowatts of electricity through multiple electrical outlets.

Reduced Maintenance and Equal Safety

EVs typically require less maintenance than conventional vehicles. They must meet federal safety standards and undergo the same rigorous safety testing as conventional vehicles sold in the United States. Learn more about EV maintenance and safety.

Flexible Charging

EVs can fuel at fleet facilities or public stations. Facility charging enables EVs to charge overnight and during idle times. Public direct-current fast-charging (DCFC) stations are increasingly available along major transportation corridors to extend EV range for longer trips. Plug-in hybrid electric vehicles (PHEVs) can fuel with gasoline/diesel at traditional fueling stations when necessary, adding even more flexibility.

Meeting Fleet Goals and Requirements

Because of their high efficiency and low-emissions benefits, EVs can help organizations meet environmental objectives, demonstrate community leadership, improve their public image, and differentiate themselves from competitors. Highly visible fleets (transit/school buses, police vehicles, taxis) can project a positive image by using EVs. Additionally, EVs can help public fleets meet Energy Policy Act (EPAct) requirements and comply with state or local alternative transportation policies.

Learn more about EV benefits.

Charging EVs

Charging at a Fleet Facility

Fleets have many options for charging at their facilities. Level 1 charging equipment may be sufficient to meet the charging needs of PHEVs. Level 2 equipment can easily charge a typical EV battery overnight, making it a good fleet option. Opting for portable Level 1 or 2 units can add flexibility and reduce overall project costs. Instead of installing a pedestal at each EV parking location, 120/240 V receptacles may be installed to support lower cost portable EV chargers that can be stored in fleet vehicles. These portable units are simpler to replace if maintenance issues arise, mitigating EV charger down-time.

Because DCFC can add up to 100 to 200+ miles of range in 30 minutes, it can be a good option for fleets that need to charge between shifts with short dwell times and may share the charging equipment among multiple vehicles. It can also be a good option for scheduled overnight charging at off-peak electric rates, as can Level 2 charging. This type of "managed" charging is made easier by using a networked charging system. Fleets should ensure charging is available for all fleet vehicles, as light-duty and heavy-duty vehicles may need separate charging units or cables. Learn more about charging infrastructure options.

Charging in Public

Fleets may have the option of using public charging stations. This could be a long-term solution for fleets with easy access to public charging that meets fleet needs, or a short-term solution for a fleet to use while developing its own on-site infrastructure.

Most public stations use Level 2 charging equipment to enable charging where vehicles are highly concentrated (shopping centers, city parking lots, airports, hotels, etc.). However, the fastest-growing charging segment is DCFC, with stations popping up along highway corridors nationwide.

Some charging stations offer free charging (at least for a short amount of time), but most are moving toward a pay-for-use system. A number of payment models are in place, such as registering for a network subscription and using a phone app for payment.

EVs in Fleet Applications

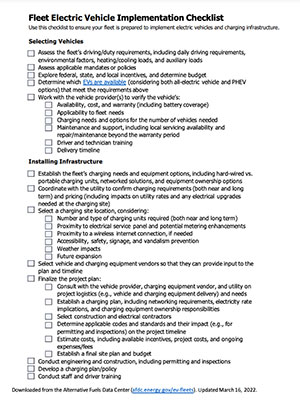

Fleet Electric Vehicle Implementation Checklist

Use this checklist to ensure your fleet is prepared to implement electric vehicles and charging infrastructure.

Many light-duty vehicles are available for fleet applications. Although some new models are limited to certain states, many are or will soon be available nationwide. MD/HD vehicles are also available for many fleet applications. In addition to federal and state incentives for light-duty EVs, some medium-duty EVs also qualify for such incentives. Many off-road EVs are also available, including forklifts, mowers, agricultural tractors, and airport ground support equipment. Vehicle upfits are available for MD/HD vehicles as well, and this can greatly increase the number of options available to a fleet.

See Selecting Fleet EVs below for some basic steps in the acquisition process.

Safety and Maintenance

From the original equipment manufacturer (OEM), EVs are very safe and undergo rigorous safety testing to meet federal requirements. Their electrical systems require little maintenance, but battery life and warranties should be well understood upfront. For more information, see the EV maintenance and safety page.

Training

Fleets should consider training for EV drivers and vehicle technicians. Technicians will need to be trained in repairing and maintaining the vehicles, and drivers will need to be trained in the use and charging of the vehicle. See Implementation and Training for more details.

MD/HD Vehicle Considerations

Many fleets use larger vehicles to meet their needs, and these vehicles bring with them even more factors to consider.

Vehicle considerations:

-

Several MD/HD EV models are available for applications such as school and transit buses, delivery service vehicles, and refuse trucks. These applications tend to have a return-to-base duty cycle (for central fueling) and shorter, predictable routes that are well-suited to current EV capabilities. However, vehicles are also available or in development to meet other fleet needs.

-

Initial vehicle production quantities can be limited, resulting in longer delivery times for some MD/HD EVs, so early planning is advisable.

-

MD/HD vehicles can be more impacted by factors that can reduce range, such as heating/cooling loads, high driving speeds, significant cargo loads, and auxiliary power use in power takeoff, auxiliary power units, etc.

Charging considerations:

-

Level 2 equipment can meet the needs of MD/HD EVs with moderate daily utilization or long dwell periods (school buses charging overnight, for example).

-

DCFC can add 100 to 200+ miles of range in 30 minutes, giving it the ability to charge multiple vehicles per day.

-

MD/HD vehicle charging equipment may have different applications than those of LD vehicle equipment. For example, some transit buses can be ordered with overhead conductive charging equipment, and some manufacturers are testing inductive wireless charging equipment. An advantage to these systems is that charging begins automatically once the vehicle is parked in the correct position.

Selecting Fleet EVs

The first step for a fleet is to assess candidate vehicles' driving and duty requirements, then apply relevant policies/incentives, and address cost considerations.

Driving/Duty Requirements

-

A fleet should first determine the vehicle's specific operating needs to be met, as these have an impact on the vehicle's range. Factors to consider:

-

Daily driving requirements (routes/miles, stop-and-go vs. highway driving, etc.)

-

Environmental factors like weather (e.g., extreme cold) and terrain (such as mountain driving)

-

Heating/cooling loads, their draw on the battery, and optional auxiliary power or heating/cooling units powered by diesel or another fuel

-

For MD/HD vehicles, auxiliary loads for equipment such as cranes, lifts, off-board tools, etc.

-

-

Additional factors to consider:

-

The vehicle's route, opportunities for charging, dwell times, and the availability of/potential demand for public charging stations (and the associated cost for charging there). The Joint Office of Energy and Transportation’s Electric School Bus Route Analysis Tool can assist school bus fleets in determining the bus power usage and charger power needs for their unique bus routes.

-

OEM vehicle maintenance and support

-

Whether the fleet's needs would be better met by an all-electric vehicle (also called a battery electric vehicle, BEV) or a PHEV. For vehicles driving 100 to 300 miles per day and able to plug in at night, a BEV might be suitable. If charging is available during the vehicle's idle periods, a BEV could exceed this 100 to 300-mile daily range. Otherwise, a PHEV (with a much shorter all-electric range but able to use another fuel for extended driving) might be better for extended driving.

-

Efficiency and range: Compare light-duty EVs and conventional vehicles at FuelEconomy.gov.

-

Applicable Policies

Some fleets must meet requirements under EPAct or comply with state or local alternative transportation policies. It's important to understand the fleet's requirements and how fleets can meet them by deploying EVs.

Cost Considerations

The project budget should include available funding in the short and long term to account for capital and ongoing costs, as well as available incentives for vehicles and charging infrastructure. In addition to federal and state incentives, a fleet may be eligible for incentives from the local municipality or utility provider. Your local Clean Cities and Communities coalition director can be a great resource here. Use the Vehicle Cost Calculator to estimate the total cost of ownership based on vehicle use.

Vehicle Selection

The next step is to identify available vehicles that could meet the fleet's needs. The Vehicle Search tool contains many LD and MD/HD vehicles currently available for a wide range of fleet applications. Electrified repowers are also available for MD/HD vehicles, which can add even more options. These can be new vehicles where the OEM uses an authorized company to electrify the powertrain while maintaining the factory OEM warranty.

Once a vehicle(s) is identified, the fleet should work with the vehicle provider(s) to verify:

-

Vehicle availability and cost. Public fleets will need to determine if a candidate vehicle is available through their specific procurement system (such as the General Services Administration), and private fleets may prefer to work with a familiar OEM or dealer. Also, to be eligible for certain (e.g., state) incentives, a fleet may need to choose from a list of vehicles approved under that specific program.

-

The vehicle's applicability to fleet needs

-

The vehicle's charging needs and charging equipment options for the number of vehicles needed

-

Warranties, especially pertaining to batteries and their replacement

-

Vehicle maintenance and support and the availability of local servicing. This should include a service agreement that outlines who will perform maintenance both during and after the warranty period and how (and by whom) your service technicians will be trained.

-

Driver training if offered by the provider

-

Delivery timeline.

Installing Infrastructure

Establishing Charging Needs and Options

Selecting vehicles should be the preliminary step in gauging the amount of charging equipment needed at a fleet facility. Factors to keep in mind:

-

The vehicle provider will typically offer several charging options and even specific equipment/provider recommendations. Ensure compatibility of the charging infrastructure with your vehicles with the OEM and charging provider before purchasing equipment.

-

Level 2 equipment typically requires one unit per vehicle (to enable overnight charging of all vehicles), whereas DCFC can serve multiple vehicles.

-

Although Level 2 equipment is less expensive to purchase, DCFC may reduce overall land use and installation labor costs as fewer units will be needed.

-

All-electric vehicles that drive more than 100 miles in a day may require DCFC for in-shift recharging.

-

A fleet may want to make charging equipment available to employees as well, either to share while fleet vehicles are away from the depot or dedicated for employee use as part of the overall project plan.

-

To maximize flexibility, a fleet may choose to forego installing hard-wired charging units and instead install 120/240 V outlets intended for use with portable charging units. A NEMA 14-50 outlet can be paired with an adapter to accommodate either a Level 1 (120 V) or Level 2 (240 V) portable charging unit. Portable units are much less expensive and can be easily replaced when necessary, although these sometimes lack network-connected managed charging solutions. Even if choosing this option, it's important to also consider safety and signage needs (see Determining the Charging Site Location below).

-

When evaluating equipment vendors, consider networking options. A networked charging system is connected to the internet and sends data, such as information on frequency of use, to the network services provider (i.e., charging network) and/or fleet administrator. Networked systems provide customer support to the fleet and allow the fleet to monitor and analyze charger use. Selecting equipment that uses the Open Charge Point Protocol (OCPP) version 1.6 or higher, which physically separates the appliance aspects of the charging equipment from the network backend component, enables the fleet to easily switch charging networks without expensive equipment upgrades. This prevents stranded assets by allowing any network the ability to operate the equipment in the event that (1) the fleet decides to switch charging networks, or (2) the existing provider no longer offers charging or goes out of business. OCPP is the industry standard for open access. Networking considerations include:

-

A networked station requires the site to have access to a wired or wireless internet connection or cellular service.

-

Networking allows a fleet to track charging and electricity use separately from non-charging electricity use, making it easier to calculate vehicle O&M costs.

-

Networking allows "smart" charging, or scheduling charging events (e.g., at night), to stagger vehicle charging and take advantage of lower off-peak electricity rates.

-

Non-networked charging infrastructure is not connected to the internet and provides basic charging capabilities without advanced utilization monitoring or payment capabilities.

-

The fleet will need to determine whether the charging equipment should be owned by the equipment/network provider or fleet. Equipment owned by the fleet is purchased, installed, and maintained by the fleet, which reduces overall cost and allows for full control over the equipment. In this scenario, the fleet is responsible for all associated costs, including any maintenance or repair. It's important to understand the logistics (including who will be responsible for repairs), warranty coverage, and costs associated with owning and maintaining the equipment.

-

Equipment owned by the network provider is installed and maintained by the provider, which minimizes responsibility to the fleet. Equipment purchase, installation, and maintenance costs are incorporated into the fees charged to the fleet users. In this scenario, it's important to have a written agreement covering equipment maintenance and repair, including response time and equipment down time.

-

Equipment down time can equate to vehicle down time, which can greatly impact fleet operations. Whichever scenario a fleet chooses, the implications of potential down time should be carefully considered. For example, a fleet may consider backup equipment (including portable charging units) or public charging options.

-

-

Other considerations include on-site storage (batteries) or generation (e.g., wind/solar) to shave peak power usage or provide backup power flexibility.

Working with the Utility

It's important to work with the local utility early in the process to confirm charging requirements (in both the short and long term, considering future expansion), understand the resulting electrical demand (and any impacts on electricity pricing), and determine whether electrical upgrades may be needed at the charging site.

-

The fleet should work with the utility (and vehicle and equipment providers) to analyze the fleet's electricity and charging-time needs by plotting electricity-use and time requirements for all fleet EVs. This will help in assessing electrical upgrade needs and choosing the appropriate number and type of charging units.

-

It's very important to understand the impacts of greatly increased electricity consumption, especially when several vehicles need to be charged simultaneously at high charging rates. For example, high electricity consumption could incur "demand charges" (a fee applied to your greatest power draw during peak periods, on top of the rate that you pay for the energy itself). Understanding these issues will help to determine whether a networked solution is needed to help manage them.

-

Special reduced-rate structures may be available for fleets charging EVs, although new meters may be required to take advantage of these rate structures.

-

It may be advisable to select an electrical contractor with experience in similar construction projects and bring that expert into the conversation at this point. The equipment provider may have recommendations for a qualified electrical contractor with experience in charging equipment installations, and the Electric Vehicle Infrastructure Training Program (EVITP) maintains a list of contractors trained and certified in equipment installation.

Determining the Charging Site Location

Site selection should include the following factors:

-

The number and type of charging units required in both the near and long term: If considering expansion of the EV fleet beyond the initial vehicle deployment, consider adding extra circuits, electrical capacity, and conduit from the electrical panel to support future charger installations. It's less expensive to add this extra capacity up front vs. upgrading in the future.

-

Metering: Consider installing separate meters for the EVs to track their electricity usage separately. This may help you get a special EV electricity rate from the utility.

-

Equipment proximity to electrical infrastructure: The further this distance, the more complicated and expensive the installation will be.

-

Equipment proximity to a wireless internet connection, if a networked station is planned.

-

Convenience: Equipment and EV parking should be convenient to users, but keep in mind that EVs can be parked for hours at a time for charging.

-

Avoiding hazards: Cords/wires should not interfere with pedestrian traffic or present a tripping hazard. Charging spaces should not be located near potentially hazardous areas, such as those with low visibility or high foot traffic.

-

Pooled water and irrigation: Charging equipment is designed to operate safely in wet areas, but users will be more comfortable if it is not located where water pools or where irrigation systems spray. If building in a known flood plain, consult with an electrical contractor to ensure appropriate codes and building requirements are addressed including mounting height and storage for connectors. Ensure the EV charger is waterproof (Ingress Protection ratings, such as IP66).

-

Weather and battery temperature limits: Because some EV batteries have operating- and charging-temperature limits, charging equipment may need to be located within an enclosed, climate-controlled area in extreme climates.

-

Preventing impact: Curbs, wheel stops, and setbacks should be used to prevent EVs from colliding with charging equipment.

-

Signage: Use signs that can be seen over parked vehicles to designate EV-only parking spaces.

-

Accessibility: Evaluate and address requirements for complying with the Americans with Disabilities Act (ADA), as well as state, local, and company accessibility policies.

-

Vandalism: Assess the risk of vandalism and minimize risk with preventive strategies.

Project Planning

The project plan should include the following:

-

Convening the project team: Work with the utility, vehicle provider, and charging equipment vendor to get their input to the project plans, costs, and logistics. An important logistic to consider is timing the purchase and installation of charging equipment with the delivery of vehicles (which can be especially slow/complicated for municipal organizations). Consider the project needs from the perspective of each.

-

Establishing a charging plan, including networking requirements, electricity rate implications, and equipment ownership responsibilities.

-

Selecting a construction contractor to bring the construction perspective to the team.

-

Charging station installations must comply with local and state codes and regulations and be completed by a licensed electrical contractor. Determine all applicable requirements and plan accordingly, and keep in mind that many jurisdictions have unique ordinances or regulations. The project contractor should know the relevant codes/standards and obtain approval from the local building, fire, environmental, and electrical inspecting/permitting authorities.

-

Establishing project costs, logistics, and timelines: Consider the condition and location of existing electrical equipment, which will determine the complexity of the required electrical installation. For example, an isolation transformer may be required to step electricity down to Level 2 or up to DCFC voltage.

-

Including permitting and inspections: These typically incur fees and can greatly impact the project timeline.

-

Estimating costs: Include available incentives, project costs, and ongoing expenses/fees.

-

Equipment costs may vary based on factors such as location, charging level, and type. Single connector unit costs range from $300 to $1,500 for Level 1, $400 to $6,500 for Level 2, and $10,000 to $40,000 for DCFC.

-

Installation costs may vary based on factors including the number and type of equipment, geographic location, site location and required trenching, existing wiring and required electrical upgrades to accommodate existing and future needs, labor costs, and permitting. Based on these factors, installation costs can range from up to $3,000 for Level 1, $600 to $12,700 for Level 2, and $4,000 to $51,000 for DCFC. Some heavy-duty installations can run much more.

-

-

Establishing a final site plan and budget: Note that a site installation plan may be required before charging equipment can be installed.

Implementation and Training

The final step is engineering and construction, including permitting and inspections. At this point, it may be advisable to develop charging guidelines (or an actual policy) for drivers and staff, particularly if charging equipment will be shared. It's also advisable to develop a training plan for EV drivers, vehicle technicians, fleet operations staff (e.g., those responsible for the vehicle charging effort), and even first and second responders in the area who may be called to the fleet location in an emergency.

-

Technicians will need to be trained in repairing and maintaining the vehicles, both during and after the warranty period.

-

Operations staff will need to be trained on charging logistics, which can be more complicated when many EVs and charging stations are involved.

-

Drivers will need to be trained in the use and charging of the vehicle, and this should include "refresher" training (especially when the drivers drive both EVs and non-electric vehicles).

-

For first responders, vehicle OEMs publish emergency response guides for their vehicles (most of these guides are available on the National Fire Protection Association website) and some offer training for emergency responders. The National Fire Protection Association also has training and information resources available.

-

The National Alternative Fuels Training Consortium (NAFTC) provides training for vehicle technicians and first responders.