Compressed Natural Gas Fueling Stations

VICE Model

Use the Vehicle and Infrastructure Cash-Flow Evaluation Model to evaluate payback periods for stations and vehicles.

Unlike gasoline or diesel stations, compressed natural gas (CNG) stations are not "one size fits all." Building a CNG station for a retail application or a fleet requires calculating the right combination of pressure and storage needed for the types of vehicles being fueled. Making the right choices about the size of the compressor and the amount of storage at the station will impact the cost of fuel and range for vehicles.

Types of Stations

There are three types of CNG infrastructure, including time-fill, fast-fill, and a combination of the two. The main structural differences between these two systems are the amount of storage capacity available and the size of the compressor. These factors determine the amount of fuel dispensed and the time it takes for CNG to be delivered. Most CNG stations include one of these two system types, but the third "combination fill" station type includes both systems.

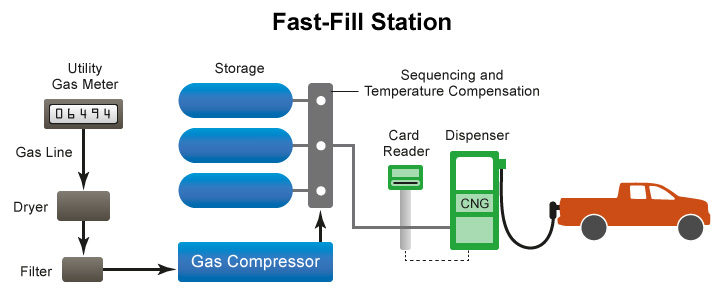

Fast-Fill Stations

Generally, fast-fill stations are best suited for retail situations where vehicles arrive randomly and need to fill up quickly. All public CNG stations have a fast-fill option. Fast-fill stations receive fuel from a local utility line at a low pressure and then use a compressor on site to compress the gas to a high pressure. Once compressed, the CNG moves to a series of storage vessels so the fuel is available for a quick fill-up. CNG can also be delivered via dispensers alongside gasoline or other fuel dispensers.

CNG at fast-fill stations is often stored in the vessels at a high service pressure (4,300 psi) so the dispenser can deliver it to a vehicle quickly. The dispenser uses sensors to calculate pressure and measure the number of gasoline gallon equivalents (GGEs) delivered to the tank, taking temperature into account.

Learn more about filling CNG tanks.

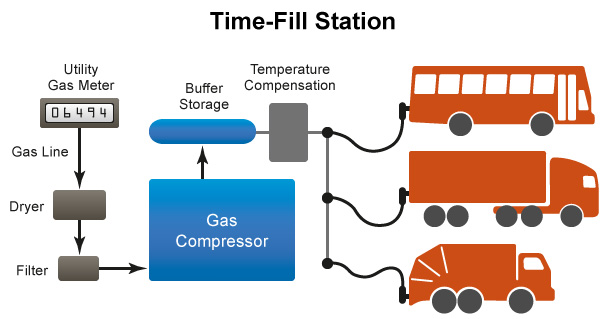

Time-Fill Stations

Time-fill stations are used primarily by fleets and work best for vehicles with large tanks that refuel at a central location every night. At a time-fill station, a fuel line from a utility delivers natural gas at a low pressure to a compressor on site. Unlike fast-fill stations, vehicles at time-fill stations are generally filled directly from the compressor, not from fuel stored in high pressure vessels. The size of the compressor needed depends on the number of vehicles to be fueled. Although there is a small buffer storage tank, its purpose is not to fill vehicles but to keep the compressor from cycling off and on unnecessarily—wasting electricity and causing undue wear and tear on the compressor. The storage tank is sometimes used to "top off" vehicle tanks during the day.

The time it takes to fuel a vehicle depends on the number of vehicles, compressor size, and the amount of buffer storage. Vehicles may take several minutes to many hours to fill. The advantage of using a time-fill station is that the heat of compression is less, and this results in a fuller fill than a fast-fill station can provide. Another advantage is that a fleet manager can control when the vehicles are filled, such as during off-peak hours (like at night) when electricity rates are lower.

Time-fill stations are carefully architected based on the intended use. For example, a transit bus company may need a larger compressor that can deliver 8 to 9 gallons per minute, while a refuse truck company can make do filling trucks at 3 gallons per minute using a smaller compressor. A consumer application may require far less—such as less than a gallon per hour. These differences account for the large variance in the cost of installation.

Learn more about filling CNG tanks.

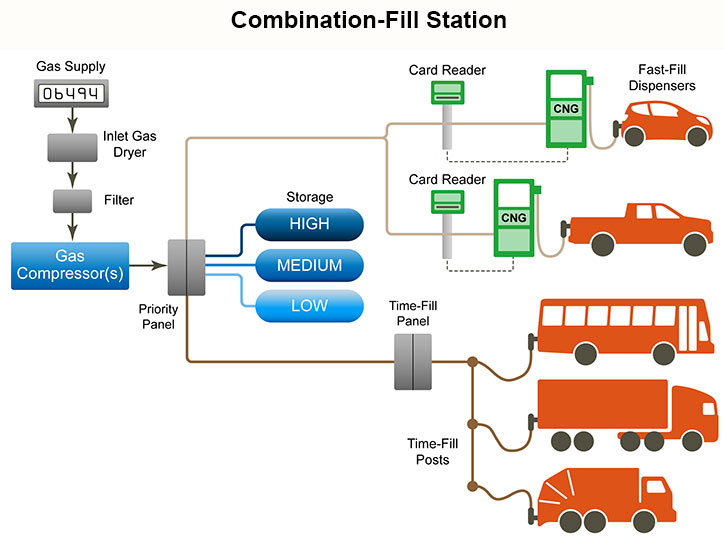

Combination-Fill Stations

Combination-fill stations include both the fast-fill and time-fill components in one system. The vehicles connected to the time-fill posts are filled directly from the compressor, usually overnight. Vehicles at the fast-fill dispensers are filled from the storage vessels or from the compressor, depending upon need. This design gives a fleet flexibility.

Combination-fill stations typically cost more to build than the previous two station types. A combination-fill station can also be a revenue source if the fast-fill dispensers are made available to the public.

Learn more about filling CNG tanks.